Laser Welding

Filigree welding applications of metals like copper, aluminum & stainless steel using a blue ultra brillant diode laser

Filigree welding applications of metals like copper, aluminum & stainless steel using a blue ultra brillant diode laser

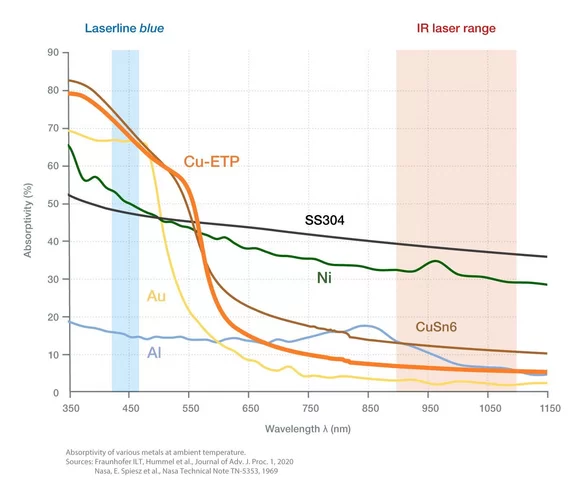

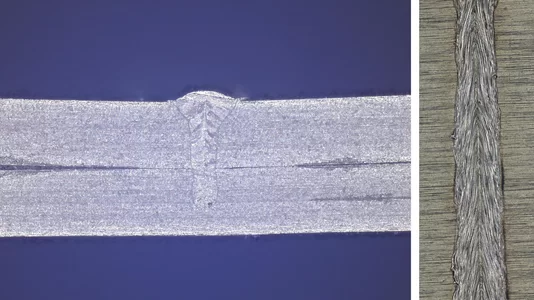

The blue laser enables controlled welding of copper and other non-ferrous metals with low material thickness. Whereas thin foils were previously cut rather than joined with an infrared laser, the blue laser can now be used to process the material in a targeted and controlled manner. The blue laser beam is used to melt the desired material along the joints. The liquefied materials flow into each other and form the weld seam as they cool. This process produces particularly smooth seams that are of excellent quality and therefore highly stable. The process is basically the same as with an infrared laser - apart from the wavelength used.

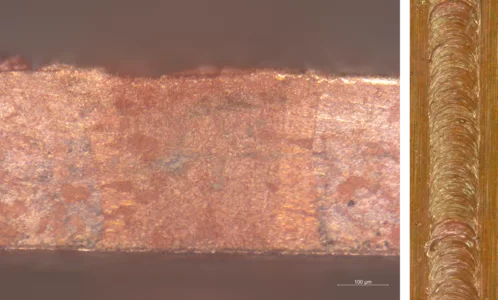

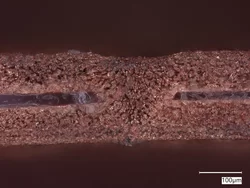

Welding of 0.42 mm copper

LDFblue 400-wbc - 6 m/min

Welding of 0.42 mm copper

LDFblue 800-wbc - 30 m/min

with LDFblue 800-wbc

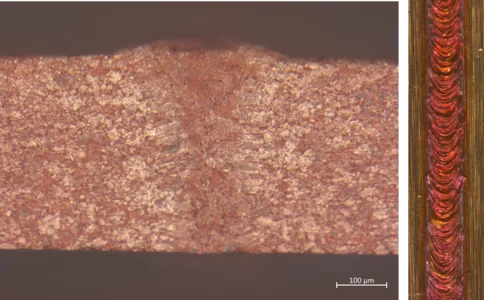

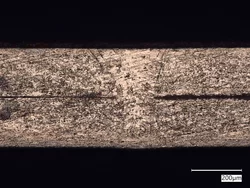

Welding of 200 on 200 µm aluminum

LDFblue 400-wbc - 12 m/min

Welding of 200 on 300 µm aluminum

LDFblue 400-wbc - 6 m/min wobbling of laser spot

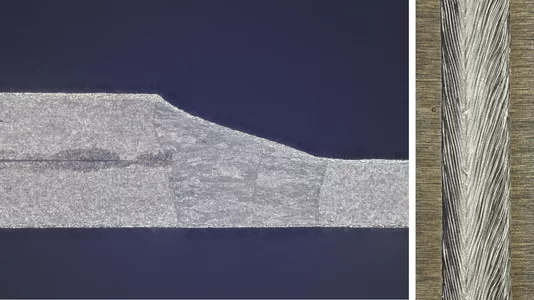

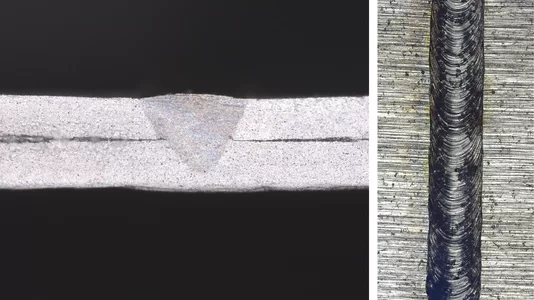

Welding of 300 on 300 µm stainless steel

LDFblue 400-wbc - 15 m/min

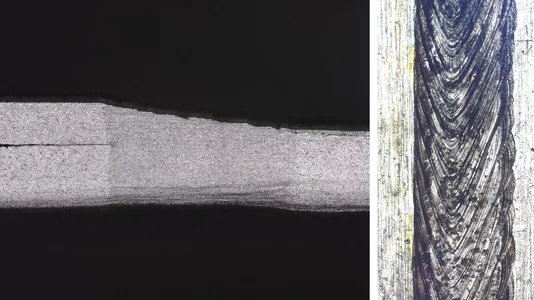

Welding of 300 on 300 µm stainless steel

LDFblue 400-wbc - 3 m/min wobbling of laser spot